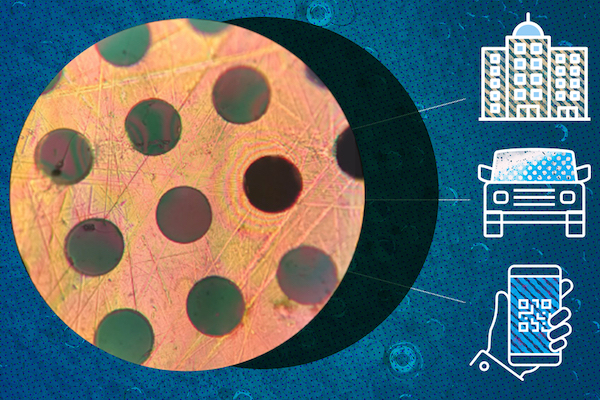

Image via MIT

Stronger than steel, lighter than plastic—it seems too good to be true, but MIT scientists have done it again.

A new polymerization process has led to a new plastic material, named 2DPA-1, which is two-dimensional and assembles itself into sheets. This is unlike other polymers in existence today, which are one-dimensional and come in the form of chains.

The best visualization resembles good ol’ reliable pasta. Regular polymers are more like spaghetti, while 2DPA-1 is more reminiscent of a lasagne sheet.

This material can be used in things like cellphones and car parts thanks to its lightweight nature, but can also be incorporated in construction of structures, like bridges, thanks to its strength. It can also be mass-manufactured, which bodes a promising future.

Previously, scientists have struggled to believe that polymers can be two-dimensional because of how fragile the structure can be, per MIT’s statement. If just one monomer rotates slightly up or down out of the plane of the sheet, the material will begin to expand in three-dimensional form.

But by using a compound called melamine, monomers are able to grow in two dimensions to form disks. These stack atop each other while being held together by hydrogen bonds, giving the material its strength.

“Instead of making a spaghetti-like molecule, we can make a sheet-like molecular plane, where we get molecules to hook themselves together in two dimensions,” explains Michael Strano, Professor of Chemical Engineering at MIT and senior author of the new study.

“This mechanism happens spontaneously in solution, and after we synthesize the material, we can easily spin-coat thin films that are extraordinarily strong.”

This “spontaneous” happening in solution means that the material is capable of self-assembling, easing production. To increase the output, researchers just need to increase the starting materials too.